Electronic Kanban - eKanban

Manufacturing companies are on a continuous quest to align their operations with customer demand while minimizing inventory through supplier collaboration.

Unlike a forecast based MRP system, Just-In-Time (JIT) Kanban is a pull based system that is driven by demand to reduce inventory and optimize the manufacturing process.

Material is requested only when it is needed. The E-Kanban approach ensures that suppliers are notified immediately when a bin becomes empty. Inventory replenishment from external suppliers or from another division within the company gets automated with E-Kanban.

TPSynergy’s cloud based collaboration system acts as a common gateway between suppliers and

buyers to see the current status of all the Kanban bins. With one common system that is accessible

to all trading partners, TPSynergy becomes a single, reliable source of information reducing inventory and

avoiding costly production bottlenecks.

Internal & External

E-Kanban can be used to refill inventory from another division within the same company or from an external supplier.

Easy Implementation

A Kanban system can be implemented in few days. You can start with just a handful of items to experiment with and then expand.

Comprehensive System

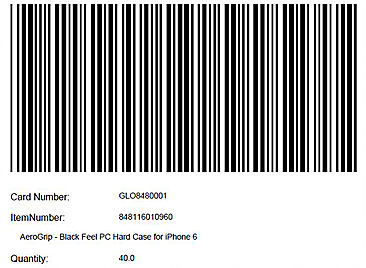

TPSynergy is a comprehensive E-Kanban system. Printing bar coded cards, scanning, and refill signals are all included

Independent System

TPSynergy’s E-Kanban system can run without an ERP system, and replenishment signal loops can be run independently.

Reconciliation Reports

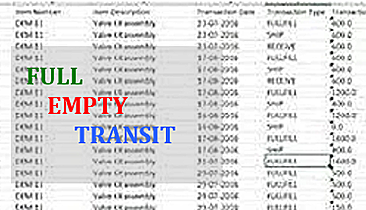

All Kanban transactions including refill requests, shipments and receipts are recorded in the system. End of month reports help invoice reconciliation

Supplier Onboarding

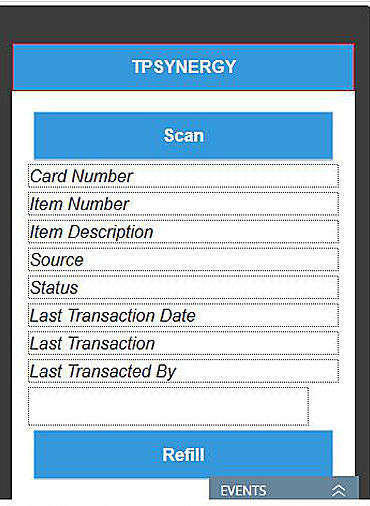

Suppliers can use either a mobile app or a web portal to view, print and transact Kanban cards. A simple, easy to use interface makes supplier onboarding easy.

How it benefits your supply chain

- The Kanban system has proven to reduce inventory by 20%

- Demand driven refill ensures no excess or shortage in inventory.

- Electronic signals ensure instant communication of demand to suppliers.

- The web interface gives a view of the current Kanban card status to suppliers.

- Bar coded Kanban cards make it easy to scan and inform suppliers.

All of these aspects are crucial for On Time Delivery

How does it work?

Mobile apps allow for

faster and more efficient

scanning

Bar Coded Bins

Transaction Reports

Are you interested? Do you have any questions or comments?

We'd love to hear from you!

+1 - 512-270-4965

Solutions

Supply Chain

Supply Chain Control Tower

Order Management

Advance Ship Notice

Electronic Integration

Inventory Visibility

Internet of Things (IOT)

Electronic Invoicing

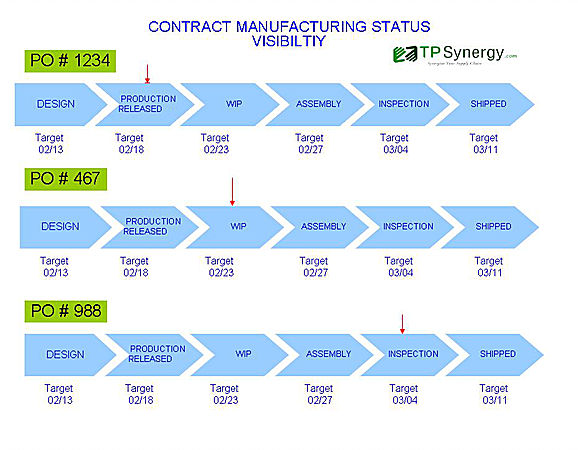

Contract Manufacturing

Efficient Receiving

Document Management

Quality Management

Real Time Monitoring

Block Chain Security

Inbound Freight Consolidation

Forecast Collaboration

Mobile Apps for Supply Chain

EDI Integrations

EDI For Amazon

EDI For Grainger

EDI For Fry’s Electronics

EDI For Home Depot

EDI For WayFair

EDI For BJ’s Audio

EDI For Cardinal

EDI For TJMax

EDI For Marshalls

EDI For Kohl

EDI For Sephora

EDI For Zappos

EDI For Royal Canin

EDI For General Mills

EDI For Pepsi

QuickBooks EDI

Shopify DropShip

BigCommerce DropShip

SKUVAULT EDI

StichLabs EDI

Resources