Why should companies have their own vendor portal to manage their suppliers ?

A few of the benefits enabled by the introduction of supplier portals include:

Broader Supplier Enablement

Portals enabled a new tier of suppliers to automate routine supply chain execution transactions such as purchase orders, ship notices and commercial invoices. EDI had gained a critical mass of usage amongst larger companies. However, smaller businesses often struggled to find the resources, budget and in-house expertise to implement EDI. Portals filled the white space in the market quickly. Anyone with a PC and an Internet connection could connect to a portal with minimal training and investment. As a result, the barrier to entry for e-commerce was lowered enabling tens of thousands of small suppliers to interact with customers electronically.

New Business Process Automation

Portals enabled a new group of business processes such as strategic sourcing, collaborative design and demand planning to be automated. Historically, these processes occurred over the phone, via e-mail correspondence or in face-to-face meetings. Due to their complex nature these supply chain practices were too sophisticated to automate through machine-to-machine transactions. By moving these processes on-line, portals reduced not only the cost of these transactions, but the latency of information sharing and the barriers to adoption.

Supplier Self-Service

Portals offer a lens into the buyer’s ERP system. Inquiries that would need to have been conducted via a time-consuming game of phone tag could instead be performed with just a few mouse clicks. For example, a high percentage of the call volume to accounts payable organizations is from collections personnel in the supplier organization attempting to determine when an invoice will be paid. Portals offer the ability for suppliers to perform self-service inquiries online whenever they need to know the status of an expected payment.

Collaborative Processes

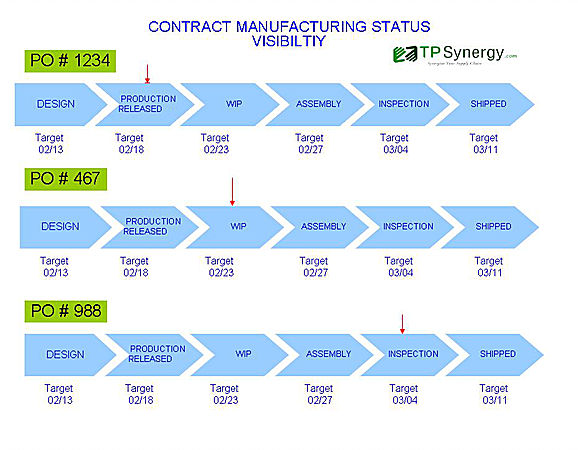

Portals provide both supplier and buyer a single, shared view of data. Historically, personnel from buyer and the supplier each viewed data in their own business applications which were hopelessly out of sync. With portals both supplier and buyer share a common view of data such as performance scorecards. The newfound visibility enables the two parties to collaborate on corrective actions to improve overall supply chain performance. Dispute resolution is another process which benefited from the shared view on a portal.

Change Management

Supply chains are constantly changing. Buyers open up new distribution centers, manufacturing plants and retail stores, which changes routing guides. As business process re-engineering occurs, new and improved forecasting, purchasing, labeling, shipping and invoicing procedures are introduced. Portals provide an online resource for buyers to communicate changes to contact details, routing guides and business processes to the supplier community. Historically, these changes had to be communicated to each supplier through direct mail, phone conversations or vendor conferences.

TPSynergy.com(www.tpsynergy.com) provides an easy to use instant vendor portal companies to launch their supply chain collaboration platform on the cloud. Case Studies provides detailed scenario how the portal solution can be used.

Leave a Reply