HOW TO MAKE YOUR SUPPLIERS DELIVER ON TIME – ALWAYS!

Every supply chain managers most important task is to ensure the Material is there – where it is needed and when it is needed.

Having said that, it is not easy to do it every time right. There are many links in the supply chain and even if one link breaks, the chain breaks. One of the important link is that the supplier delivers on time as needed by the purchasing process.

Refer this article that talks about how to motivate the suppliers to deliver on time.

http://www.ism.ws/pubs/proceedings/confproceedingsdetail.cfm?ItemNumber=11205

Even though the article is written in 1999, it is still relevant today. The key points to be noted in the article are

- Do not assume supplier has received your purchase order and will deliver according to the dates in the PO. Always make the supplier confirm in writing that they will deliver as needed or inform when they will deliver. This will need acknowledgement from the supplier for each and every PO that you send them. Preferably this acknowledgement should be system generated from the Supplier’s’ ERP system so that you are sure that their plan is according to your requirements.

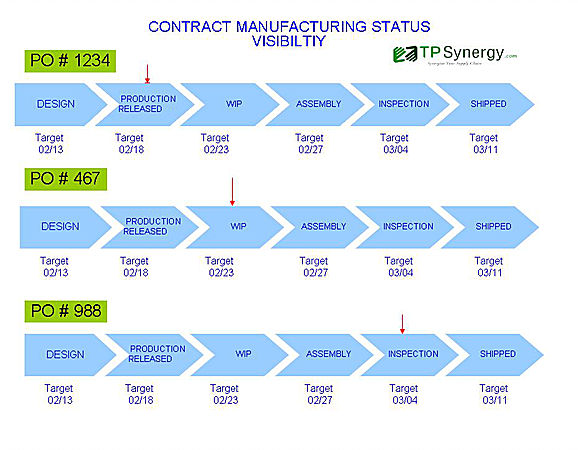

- Ask the supplier to provide you status updates. Especially in contract manufacturing or made to order scenarios, you as the Supply chain manager should be in constant touch with the Supplier to ensure their manufacturing process is in schedule. This way you can avoid last minute surprises.

- Many suppliers may work on Ex-works basis. That means once the material leaves their plant, their responsibility ends. But you as the supply chain manager, need to ensure that the material reaches your docks in time. You need to know when the supplier has shipped the material and also tracking details.

- Insist to the supplier that they provide Advance Shipment Notification (ASN) always when they ship material on your purchase order. Ensure that they provide Freight forwarders’ tracking details.

- Track the shipment till it reaches your works. Even though the shipping industry is very efficient today, everyday lot of packages gets lost in transit. If your shipment is not hitting travel milestones, you are not going to get it in time.

- Measure your suppliers meticulously on their delivery performance. Each and every delivery of your supplier should be compared to when it was needed, when it was promised and when it was delivered. This is a continuous evaluation process and Supplier should be informed of the results. Ensure that this feedback reaches the right people in the supplier’s Organization as high as possible

- Use electronic tracking as for as possible. RFID technology helps to track the items in a large warehouse and monitor the movements.

- Do not put all your eggs in one basket. It helps to develop multiple sources for each critical product. Even if one source fails, you always have the alternate available.

If you do all the above, most likely you will not have the nightmare situation of delayed deliveries, stock out, customer corrective actions and get better sleep in night. Using a Supply chain collaboration solution like Tpsynergy (www.tpsynergy.com) helps to ensure your deliveries are always on time.

Leave a Reply