Electronic Kanban (E-Kanban) System Explained

What is the Kanban system?

Kanban is a Just in Time (JIT) concept where restock orders for more inventory are sent only when current inventory is empty or low. In practice, the customer has two bins of the required product. When one bin is empty or running low, the other bin is used while a restock order is sent and fulfilled by the supplier.

.

What are the benefits of this system vs. forecast-based MRP?

A traditional forecast based MRP system, where material is ordered and restocked based on previous demand, is prone to both shortages and surplus. These problems can occur often when demand fluctuates or in case of unforeseen circumstances, such as shipment delays, In contrast, the Kanban system is resistant to these changes due to the inbuilt buffer of inventory, and restocking only ordered when needed.

E-Kanban vs Manual Kanban

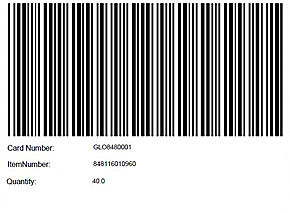

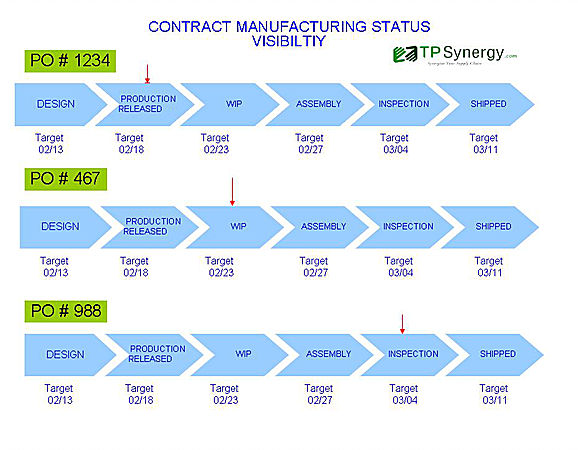

Even with the Kanban system’s benefits over MRP, a manual Kanban system can be slow and inefficient. Mailing times, business hours, and human error can severely limit or impede the system, causing trouble within the supply chain. This is why an Electronic Kanban (E-Kanban) system is superior to a manual one. In an E-Kanban system, barcodes are scanned using a scanner and the status is sent to suppliers electronically. There, orders can be fulfilled instantly and without human interaction and are sent back to the customer. This solves the aforementioned problems and allows the supply chain to flow smoothly. In addition, E-Kanban systems can be implemented with ease, such as with TPSynergy.

Leave a Reply