Electronic Kanban (E-Kanban). How Does it Work?

Kanban

Two Bin E-Kanban System

Kanban is a Just in Time (JIT) manufacturing system introduced by Japanese manufacturing companies to optimize inventory management. The basic principle of Kanban is that “Produce or Order only what is needed and when it is needed”

Closed Loop System

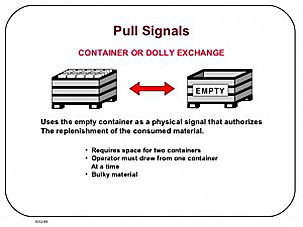

Kanban is a closed loop system that uses consumption based replenishment instead of forecast based replenishment. Inventory control is achieved by using bin system. Material is stocked in bins and each bin represents one Kanban card. When the bin becomes empty, it triggers a demand signal to the source. The source can be internal manufacturing or an external supplier.

Why is it better than a MRP System or ROP System

Material Requirement Planning (MRP) system depends upon the accuracy of the demand forecast for the end product and current inventory in stock. As the demand for the end product may fluctuate widely, it leads to either excess inventory situation or stock out situation.

How Does the Kanban System works

Kanban process can be easily understood by the three bin system. Consider a Plastic Bottles Manufacturing company. They make the bottles, buy the cap from a supplier and assemble them together. There will be three full bins of bottle caps. One bin at the point of manufacturing, one full bin at the store room and one full bin with the supplier.

Bar Coded Bin

As soon as the bin at the point of manufacturing becomes empty, the bin will be returned to the Stores and replaced by the full bin from Stores. Stores in turn will send the empty bin to the Supplier in replacement for a full bin.

Each bin will have a coded card called Kanban card. It will have details like Item number, quantity per bin and how many bins are in circulation.

As can be seen in the above process, it is a closed loop system like a water supply sytem. It never runs out and there is no wastage.

Manual Vs Electronic Kanban System

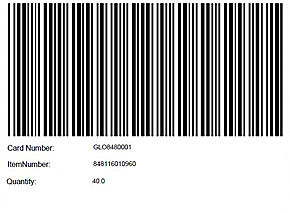

Bar Codes for Each item

In a manual kanban system, everything depends upon the manual Kanban card. If the card gets lost or duplicated, it will lead to mis managed inventory. Also the signal does not get triggered till the physical bin and card reaches the next point.

In an Electronic kanban system, all cards are maintained electronically.. There will be printed copies of the kanban card but there is a central system maintaining the cards. Barcoded kanban cards are scanned as soon as it becomes empty. This will trigger an instantaneous replenishment message to the supplier so that material can be shipped right away instead of waiting for the physical bin to reach.

How to Implement a Electronic Kanban System

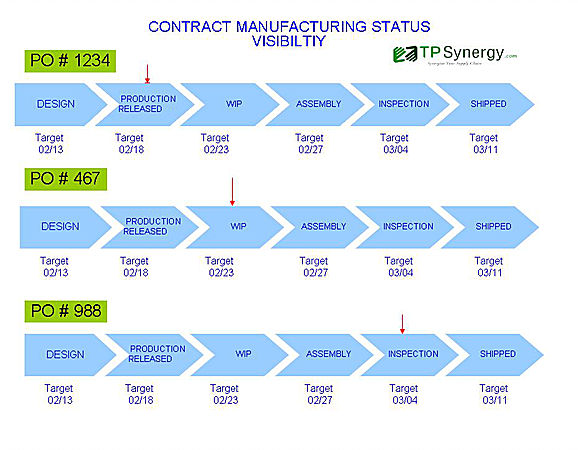

Supply chain solution companies like TPSynergy provides an electronic version of the kanban system that is easy to get started with.

Identify few key items that are consumed regulary and supplied by suppliers located nearby. Shorter lead time helps to build an efficient Kanban system.

Run regular inventory health reports to monitor how the Inventory system is maintaining the correct inventory.

Benefits can be seen almost immediately by implementing the kanban system.

Leave a Reply