Dynamic Supply Chain

Dynamic Demand Drives Dynamic Supply Chain

Dynamic Demand Fluctuation makes the Supply Chain also Dynamic.

Dynamic Demand Fluctuation makes the Supply Chain also Dynamic.

Companies are pushing the inventory down the lane to suppliers and would like to delay their procurement as late as possible.

Many of the large retailers like Amazon, Home Depot are insisting on very short delivery window of 3 days. They expect to procure and ship with in the same week.

This is possible in case of retailers who buy finished goods and ship the same without any added process on their side. But for Manufacturers, this will not be possible as they need to stock the raw material to absorb the long lead time and fluctuations in the demand.

Frequent Orders and Order Change

Purchase order

Before Lean manufacturing and Lean procurement concepts became widely adopted, manufacturing companies were forced to stock large inventory to avoid risks in lead time.

With today’s dynamic market, it is not possible to have the luxury of 3 months of consumption in the warehouses. At the maximum it is only a week’s requirement is stocked.

This leads to more frequent orders with smaller quantities. Just in time (JIT) and Kanban are the driving factors here. Blanket price agreements are followed by many small releases. Also these orders are frequently changed due to fluctuation in demand.

MRP Driven Order Management Night Mare

Almost all companies today use Material Requirement Planning system to plan their procurement.

Almost all companies today use Material Requirement Planning system to plan their procurement.

These MRP systems will use the demand and demand changes to drive the procurement. This will cause many automated changes to the orders in process. Combining this with the small volume orders, it causes a volume of orders and order changes to manage.

Will the Supplier ship the right order and right Quantity

On an average, a company may have 20 -30 open orders to the same supplier at any given time. These open orders also undergo many revisions as MRP will constantly be suggesting changes to these orders to honor the dynamic demand.

On an average, a company may have 20 -30 open orders to the same supplier at any given time. These open orders also undergo many revisions as MRP will constantly be suggesting changes to these orders to honor the dynamic demand.

How to ensure that the supplier is having the latest updated orders and will ship the right quantity. In many cases, it so happens that supplier is not having the latest updated order and they might be shipped to a previous version of the order.

Problems in Receiving Dock

Forklift carries a box in storage. Flat banner production process in Warehouse. Vector illustration for business, info graphic, web, presentations, advertising.

It is a common scenario that the receiving doc receives a shipment for an order that was cancelled already, or the quantity has been reduced.

Should the shipment be returned to the supplier or stowed away for future orders. Receiving dock always has this problem due to the constant change of orders.

Supplier Portal and Change Management

Single Data Repository

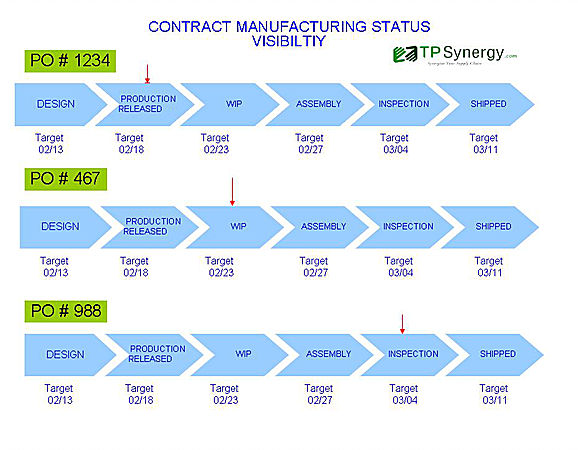

Imagine if customer and suppliers are using the same system to manage the orders. Any changes to the orders are immediately updated in this common system and shipments are created only based on the data in this system.

This is best benefit of a Vendor Portal or Supplier Portal that will ensure that the current changes to orders are updated immediately in the portal and portal is the common one source of truth for managing the orders.

TPSynergy provides such portals out of the box and easy to implement. Contact TPSynergy to discuss more on the benefit of these portals.

Leave a Reply