COLLABORATION IN THE SUPPLY CHAIN

Technology today, enhance collaboration in Supply Chain to a great extent

A recent trend in the supply chain and collaboration focus on joint planning, coordination and process integration between suppliers, customers and partners in a supply chain, collaboration is meant to overcome the challenges in Supply Chain and has the advantage of faster product output, reduction of production and logistical cost, increase of efficiency as well as maximizing return on investments for all members

This is an interaction supported by a technology between two or more parties that play a role in the supply chain in order to achieve a common objective for mutual benefits, basically collaboration is becoming very important in the supply chain as an approach to competitive advantage through reducing cost and improving service level.

The collaboration between the two parties through sharing of information includes features like order and back order change management, order tracking as well as proof delivery reporting, returns and claims entry workflow. With these features both parties are guaranteed of high efficiencies as application and administration costs are reduced due to a common database used by both the parties.

Online collaboration leads to a better customer experience, this is through the fact that customer can make online demands from anywhere. Online collaborations are prompt, fast and accurate

Email, Phone calls are not as effective for an efficient collaboration. A collaboration software to enhance the process like for instance TpSynergy.com (www.tpsynergy.com) solutions that streamlines supply chains operations from planning ,forecasting, sourcing production warehousing production and the whole process. Supply chain software’s work together with information from enterprise resource planning software and customer relationship management. This integrations software’s has the advantages of improving the supply chain network, minimize delays, and enhance collaboration as well as reducing the overall costs. Supply chain software is fractured into groups of software to perform different tasks although they have some challenges when installing on premise as it needs technical expertise. Hence a cloud based software to manage collaboration is preferred.

The supplier rating is very important in the overall entire supply chain as whole, supplier performance rating solves the problem of differing measuring units by normalizing performance data. The rating is designed rank supplier when considering multiple performance criteria the method provides a method of scoring and comparing suppliers, here data on performance Is collected is used in evaluating supplier. Supplier rating has a lot of uses

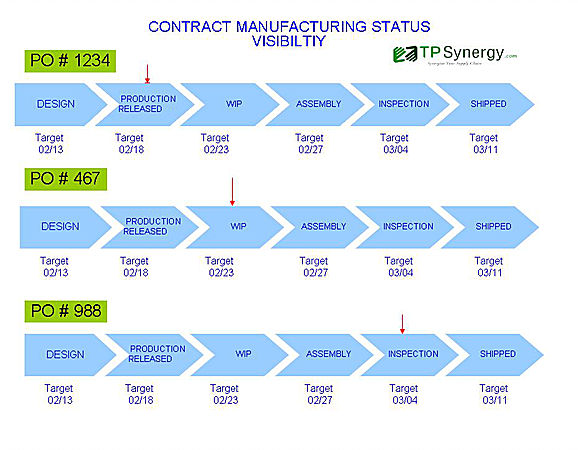

inventory management software, such as TpSynergy.com (www.tpsynergy.com) provides the business with a complete set of inventory manufacturing, management and purchasing capabilities that will see an improvement in chain supply management in addition to the delivery of an end to end procure to pay process.

With the inventory software, the business will gain a real- time, in depth view into the main inventory, supplier and procurement indicators. This is in addition to self-service capabilities for the vendors, partners as well as customers and thus improves collaboration in the entire supply chain. The software allows for a better level of manage inventory and cost that will enable the business to meet and fulfill expectations, improve customer care service and achieve goals.

Some of the main features on the software may include

- warehouse and inventory control,

- purchasing and vendor management,

- optimizing manufacturing process,

- demand planning,

Benefits

There are a number of benefits that come along with the application of the software. These include

- A full real time visibility into supply, demand, fulfillment measures and costs and trends,

- Margin management with a better view in to inventory costs, inventory profits and turn rates,

- The ability to eliminate manual inventory management processes and thus improve satisfaction for the vendor with a seamless procure to pay process,

- The business will have a better opportunity to effectively and efficiently meet demands of the customers and thus help in driving and maintaining superior customer service levels,

- Be able to meet the industry’s specific inventory management and purchasing needs using easily integrated add on solutions that are available from the company that developed the software

Leave a Reply