Extend your ERP to the Supply Chain

A Testimonial From Our Customer

“We searched for EDI solutions, but many were custom built from scratch and would’ve cost us tens of thousands. We found TPSynergy and went through their intro demo. It almost seemed too good to be true. We would highly recommend this for anyone looking for an EDI solution.”

Sean Bush

Founder of Puracy

Founder of Puracy

Are you interested? Do you have any questions or comments?

We'd love to hear from you!

+1 - 512-270-4965

Solutions

Supply Chain Control Tower

Order Management

Advance Ship Notice

Electronic Integration

Inventory Visibility

Internet of Things (IOT)

Electronic Invoicing

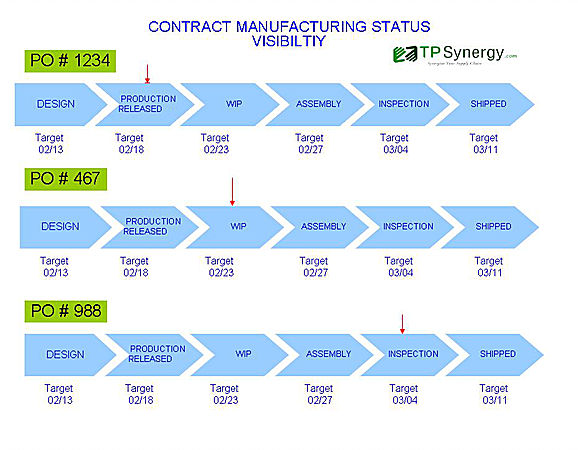

Contract Manufacturing

Efficient Receiving

Document Management

Quality Management

Real Time Monitoring

Block Chain Security

Inbound Freight Consolidation

Forecast Collaboration

Mobile Apps for Supply Chain

EDI For Amazon

EDI For Grainger

EDI For Fry’s Electronics

EDI For Home Depot

EDI For WayFair

EDI For BJ’s Audio

EDI For Cardinal

EDI For TJMax

EDI For Marshalls

EDI For Kohl

EDI For Walmart

EDI For Sephora

EDI For Zappos

EDI For Royal Canin

EDI For General Mills

EDI For Pepsi

QuickBooks EDI

Shopify DropShip

BigCommerce DropShip

SKUVAULT EDI

StichLabs EDI

Resources