Supply Chain – Integration, Visibility and Collaboration

Supply Chain Integration leads to Visibility and Visibility leads to Collaboration. Collaboration leads to success. Let us try to define each of these components and see how they play together in a supply chain.

Supply Chain Integration leads to Visibility and Visibility leads to Collaboration. Collaboration leads to success. Let us try to define each of these components and see how they play together in a supply chain.

Supply Chain Integration

Integration in a Supply chain is the process of bringing together People, Systems and Process into one common platform. Integration is the starting point in a collaborative supply chain. Let us consider the nodes in a supply chain. A supply chain has the typical nodes as below

Customer

Customer- Supplier

- Warehouses

- Transportation Provider

Each of these nodes plays a key role in the supply chain. Each of these nodes also use their own system. For example, customers use their ERP to create orders and suppliers use their ERP to process the orders. These two systems should be talking to each other in real time to get the benefit of Integration. That is system to system integration. We also need people on the supply chain to be integrated on the process. For example, Buyer might be interested in expediting a specific order, but supplier may be prioritizing some other order. This needs to be integrated

Supply Chain Visibility

Senior business man searching new opportunities for his company

Visibility is the availability of information at the right level and the right time. In supply chain, visibility is needed in different areas as seen below

- Order Visibility

What are the orders are open, what needs to be executed on priority, has suppliers received and confirmed the order, is the order on track? All these aspects are under order visibilit

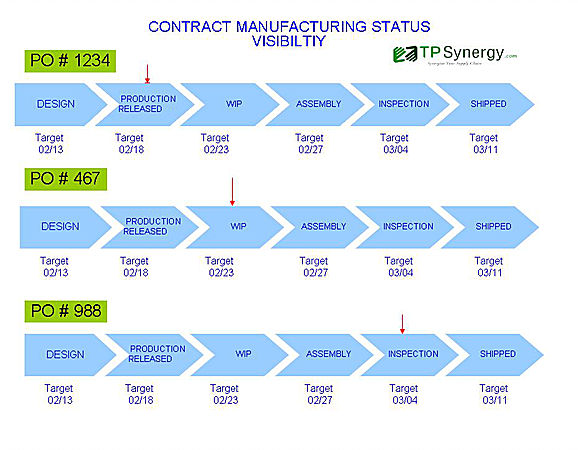

- Order Status Visibility

This is more applicable in the contract manufacturing scenario. As the order progresses through various stages like Design, Development, Manufacturing etc. Order status visibility is needed to the Buying organization.

- Shipments Visibility

Shipments status visibility is to view what orders are currently being shipped, where are they in the transit now, when it will be expected to arrive.

- Receipts Visibility

Receipts visibility is needed for the suppliers to ensure that the material they shipped has been received and accounted for. This will avoid future issues when the invoices are paid.

- Quality Visibility

Quality visibility will tell the suppliers if there were any quality problems on the shipments. Were all the material they shipped got accepted. What were the quality issues on the shipments?

- Demand Visibility

This is also the forecast visibility. What is the expected demand in the near future. These demands are not firm orders yet, but supply chain needs to have the visibility of what to expect.

Supply Chain Collaboration

Male High School Basketball Team Playing Game

A basketball team in action is a good example of collaboration. There is a clear signal from the player what he intends to do with the ball and the team members will know what to do to get the ball. In Supply chain also, this kind of collaboration is needed.

Each member in the Supply chain clearly communicates what they need from the other members of the chain. For example, the buyer clearly communicates what they need and when they need. Supplier communicates what they can do and when they will do. Once communicated, each member executes what they communicated. Suppliers deliver what they promised to deliver

Right Tool for the Right Job

screwdriver and screw on old white wood, wrong tool for the job idea, put the right man on the right job concept

Only a correct tool should be used for the correct job. It is not possible to achieve Integrated supply chain by using Email, Phone collaboration only. Companies need a true supply chain visibility and integration tool to achieve this. Supply chain collaboration portals like that of TPSynergy should be used to manage the Supply chain collaboration.

Leave a Reply