Inventory Visibility in Contract Manufacturing

Contract Manufacturing on the Mechanism of Metal Gears.

Contract Manufacturing is being widely adopted in industries nowadays. It was very popular in electronic industries. Everyone knows that Apple manufacturers most of its products with its contract Manufacturers. While Research and Development is done by the product owners, manufacturing execution is outsourced to contract manufacturers.

Contract Manufacturing can be of two major types

Consignment or Turnkey manufacturing. In Consignment manufacturing, all necessary material is procured by the product company and delivered to the contract manufacturer. In outsourced model, contractor is responsible for the procurement of the raw material and deliver the finished products.

Inventory Management Risk

In both the models, there is an imminent risk of inventory management. If the inventory located at the contract manufacturer is not managed correctly, it may lead to out of inventory situation bringing the entire supply chain to a standstill.

In both the models, there is an imminent risk of inventory management. If the inventory located at the contract manufacturer is not managed correctly, it may lead to out of inventory situation bringing the entire supply chain to a standstill.

MRP and Contract Manufacturing

While MRP (Material Requirement Planning) systems are good at planning the inventory owned by the company, they may not be able to plan the inventory needed by the contract manufacturer accurately. This is since the Bill of Material (BOM) may not be exploded to sub component level to forecast the material requirement accurately.

Inventory Accuracy at Contract Manufacturer

inventory of products

Cycle counting, and inventory verification can be done frequently at the manufacturing locations to ensure there is adequate inventory available at all contract manufacturer location. But that may not be possible with global outsourced manufacturing.

The questions asked by Supply chain planners are

- Do my contract manufacturer have enough inventory to fulfill my demand in time.

- Has my contract manufacturer planned their material requirement correctly and ordered the necessary material?

- How of their current inventory is allocated for my products?

- How much of inventory is on hand available now and how much of inventory is on order to be delivered soon.

- How much of the inventory is under quality inspection?

Global Inventory Visibility

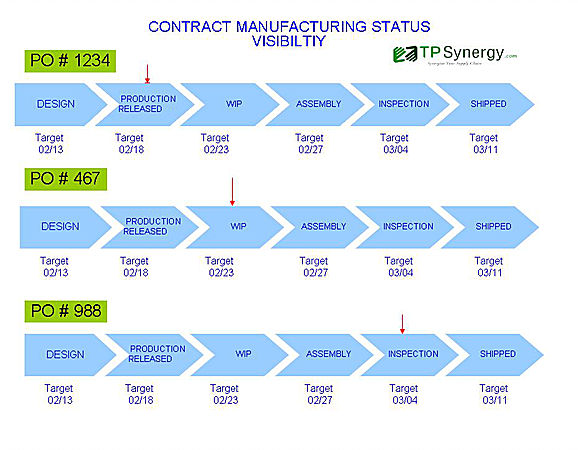

Supply chain planners need a global visibility of their inventory not only in their locations but in the extended supply chain also.

Inventory Visibility on the Cloud

Rear view of businessman standing on ladder and reaching cloud

A cloud portal for inventory visibility will provide the necessary vital input to the supply chain planners. Current status of the inventory is provided by the contract manufacturers in the cloud portal. Once the inventory is updated in the cloud portal, it is visible to everyone on the supply chain.

Providing a cloud portal is relatively simple with ready built solutions like TPSynergy.

Supply chain managers should consider providing a cloud portal for inventory management.

Leave a Reply